Metal Seat Butterfly Valve

- Metal seat butterfly valve is mainly used for water purification / water supply line and satisfies the specification of KS B2333 butterfly valve for water supply. (Certification number 99-1009)

- As the metal seat is used, there are few sources of contamination, and it is suitable for water purification/water supply lines and thus has a semi-permanent lifespan.

- There are manual, electric, and cylinder type (hydraulic and pneumatic) operation methods, and it is basically designed to operate easily even under heavy conditions.

- The worm reducer mounting position and the motor mounting position meet ISO 5210/1 standard flange specification.

- Standard

-

- 50㎜ ~ 200㎜ (※ According to customer requirements, small diameters of 50 mm or less can be manufactured.)

- Horizontal Type 200㎜ ~ 3,000㎜, Vertical Type 200㎜ ~ 3,000㎜ (※ According to customer requirements, small diameters of 50 mm or less can be manufactured.)

- Working pressure

-

- Class 1 : 0.44MPa (4.5kg/㎠)

- Class 2 : 0.74MPa (7.5kg/㎠)

- Class 3 : 0.98MPa (10kg/㎠)

- It meets KS B 2333 working pressure regulation. (※ According to customer requirements, more than 16kg/cm2 can be produced.)

- Valve joint part

-

- Flange type, standard specification is KS B 2333 and other specifications are applicable according to customer's request.

- Working fluid

-

- Freshwater and seawater (when the material is SSC16)

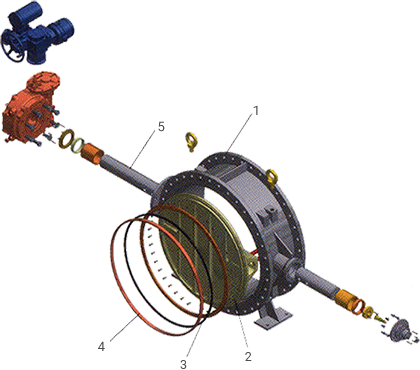

Main part material

| No | Part name | Meterial | KS |

|---|---|---|---|

| 1 | Body | Ductile Iron | GCD450 |

| Steel Structure | SS400 | ||

| Stainless Steel Casting | SSC13 / SSC14 / SSC16 | ||

| Steel Casting | SC410 / SC450 | ||

| 2 | Disc | Ductile Iron | GCD450 |

| Steel Structure | SS400 | ||

| Stainless Steel Casting | SSC13 / SSC14 / SSC16 | ||

| Steel Casting | SC410 / SC450 | ||

| 3 | Body Seat | Stainless Steel | STS304 / STS316 / STS316L |

| Bronze Casting | BC6 | ||

| 4 | Disc Seat | Stainless Steel | STS304 / STS316 / STS316L |

| Bronze Casting | BC6 | ||

| 5 | Stem | Stainless Steel | STS410 / STS420J2 / STS304 / STS316 / STS316L |

※ Other materials can be applied according to the customer's request.

Key Features

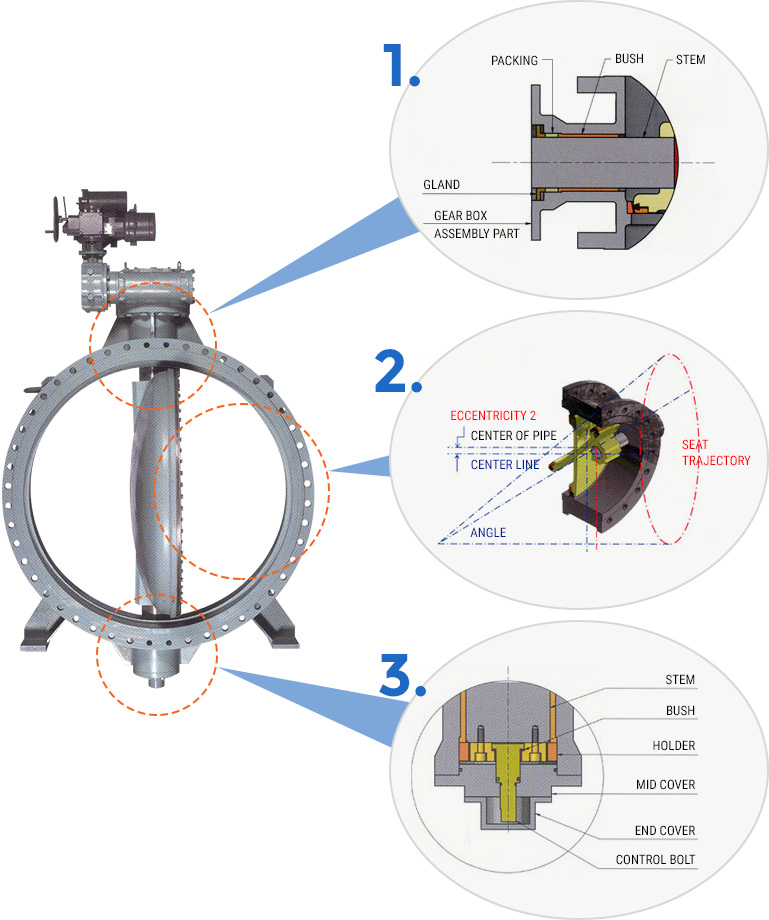

- 1. V-Packing Application

- V-packing and gland are assembled in the body boss(hub), so the gearbox is directly assembled on the body boss(hub), so the valve takes up little space, so it is easy to install in a narrow space, preventing water leakage and oil leakage can be completely blocked.

- 2. Eccentric Shape Structure

- Since the center of the shaft and the center of the diameter are eccentric, it is possible to prevent abrasion and damage to the disc seat from friction between the two metal seats during opening and closing. In addition, it is possible to prevent overload during operation, and since the life of the seat is semi-permanent, it is possible to reduce the budget of maintenance cost.

- 3. Disc Balancing Device

- By applying a double structure COVER (MIC and END COVER), it is possible to adjust the seat contact surface without disassembling the valve, so it is easy to act in case of emergency such as water leakage from the seat (Patent No. 10-123680)